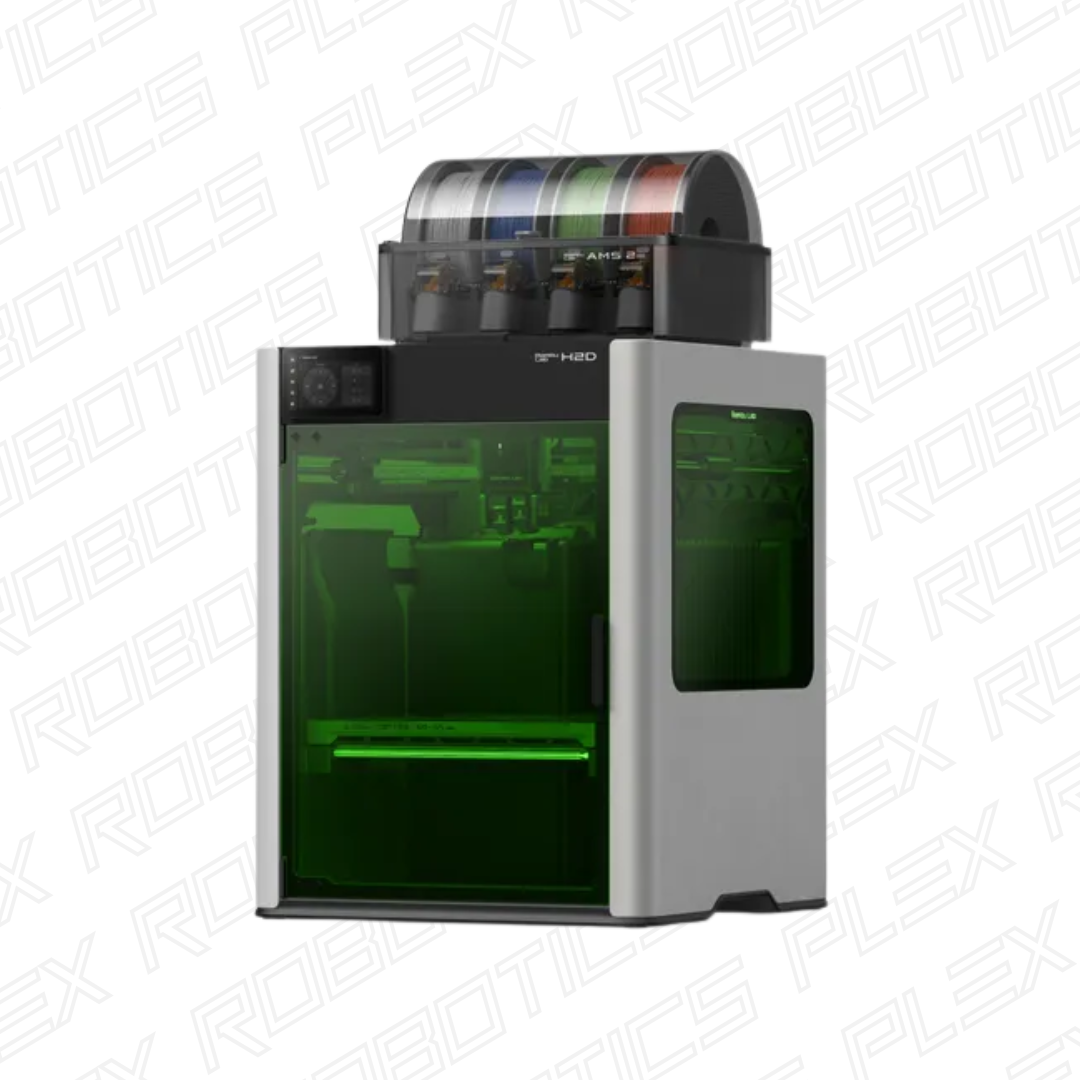

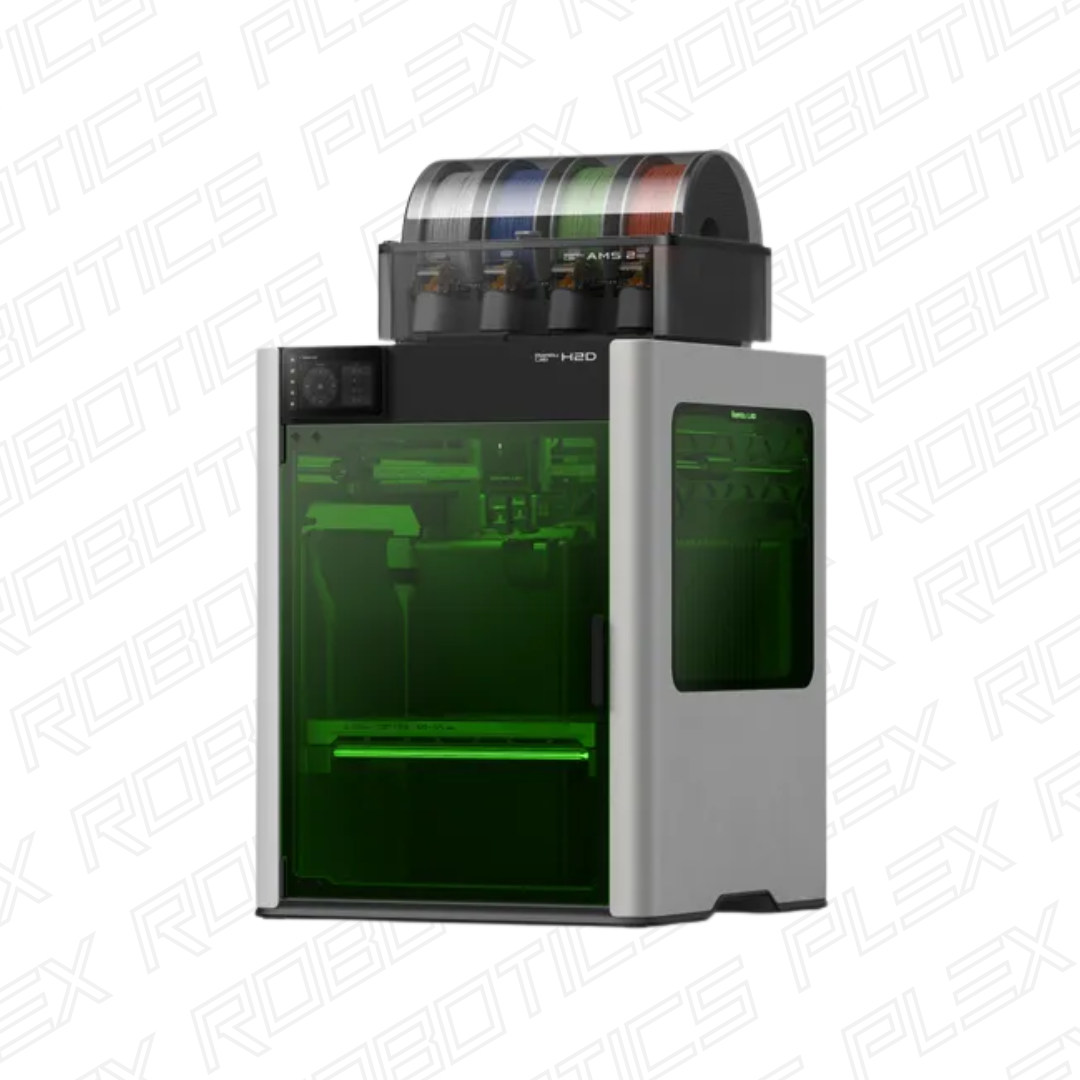

Bambu Lab

Bambu Lab H2D

Bambu Lab H2D

BAMBU-H2D-AMS📦 Final shipping cost may increase if your cart contains products from multiple vendors (e.g., 2 vendors = 2 shipping charges).

SKU: BAMBU-H2D-AMS

Couldn't load pickup availability

The Bambu Lab H2D is an advanced, all-in-one personal manufacturing system that combines dual-nozzle 3D printing, laser engraving and cutting, and digital plotting into a single, high-precision machine. Key features include a large build volume of 350x320x325mm, a high-temperature hotend reaching 350°C and an active heating chamber up to 65°C, and a comprehensive network of 15 sensors for material flow monitoring. The H2D also boasts an AI-powered system with multiple cameras and sensors for automated detection of print issues, offering a versatile and automated solution for hobbyists and professionals.

Key Features

All-in-One Manufacturing: Seamlessly switches between 3D printing, laser engraving, and plotting.

Dual-Nozzle System: Allows for multi-material printing and increased efficiency.

High-Temperature Printing: A hotend capable of reaching 350°C and an active heating chamber of 65°C to support advanced filaments like ABS, ASA, PC, and carbon fiber reinforced materials.

AI-Powered Automation: Features four computer vision cameras, 36 strategic sensors, and two servo motors to monitor and manage prints, reducing failures like clogs and spaghetti prints.

Large Build Volume: Offers an expansive print area of 350mm x 320mm x 325mm.

Advanced Material Monitoring: An intelligent sensor network tracks filament feeding velocity, tension, tip location, and extrusion pressure to ensure consistent flow.

Optional Laser Module: A 10W or 40W laser and cutting module is available for engraving and cutting wood, acrylic, and other materials.

Precision Alignment: Utilizes a BirdsEye camera and computer vision for highly accurate alignment, with a reported precision of up to 5μm.

AMS Compatibility: Supports up to 25 colors when combined with multiple Bambu Lab Automatic Material Systems (AMS), which can even dry filaments during printing.

Benefits

Versatility: Capable of handling a wide range of tasks from complex multi-color prints to detailed laser engravings.

Efficiency: The intelligent automation and multi-nozzle system significantly speed up the manufacturing process.

Ease of Use: AI-powered monitoring and pre-flight checklists help to simplify operation and improve user experience.

Precision: High-resolution optical motion calibration and advanced sensing contribute to exceptional print quality and accuracy.