Bambu Lab

Bambu ABS-GF - FIlament with Spool

Bambu ABS-GF - FIlament with Spool

PLX-17-0065-0001📦 Costul final de transport poate crește dacă în coș se află produse de la mai mulți furnizori (ex: 2 furnizori = 2 taxe de transport).

SKU: PLX-17-0065-0001

Nu am putut încărca disponibilitatea pentru ridicare

Bambu ABS-GF

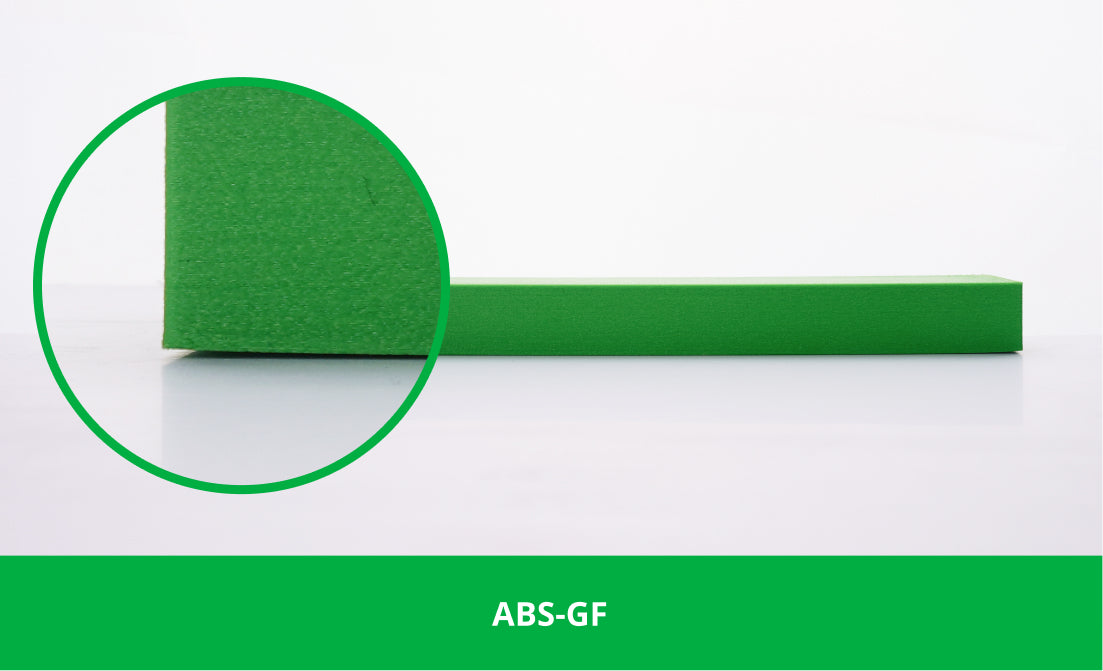

Bambu ABS-GF is a glass fiber-reinforced ABS filament, enhanced in both mechanical and aesthetic properties. Compared with regular ABS, ABS-GF outperforms in strength, stiffness, temperature resistance and dimensional stability, while being less prone to deformation and warping. Glass fiber imparts a smooth matte finish with micro-spot gloss, blurring layer lines. ABS-GF is ideal for both mechanical parts and decorations due to the inherited water resistance, wear resistance, durability and vibrant colors.

Enhanced Strength and Stiffness

ABS-GF outclasses regular ABS in strength and stiffness, making it perfect for load-bearing and bending-resistance parts.

| ABS |

ABS-GF

|

Improvement % | |

| Stiffness (Bending Modulus - XY) | 1880 MPa |

2860 MPa

|

52.1%

|

| Strength (Bending Strength - XY) | 64 MPa |

68 MPa

|

6.3% |

| Layer Strength (Bending Strength - Z) | 39 MPa |

46 MPa

|

17.9% |

| Heat Resistance (HDT, 0.45 MPa) | 87 °C |

99 °C

|

13.8% |

Greater Dimensional Stability

Glass fiber reinforcement gives ABS-GF better dimensional stability than regular ABS, minimizing warping and deformation during printing. This makes it ideal for intricate mechanical assembly parts or geometric components.

Specimen Test: Model size (L*W*H): 240*50*20 mm³ (the XY direction); Infill Density: 25%

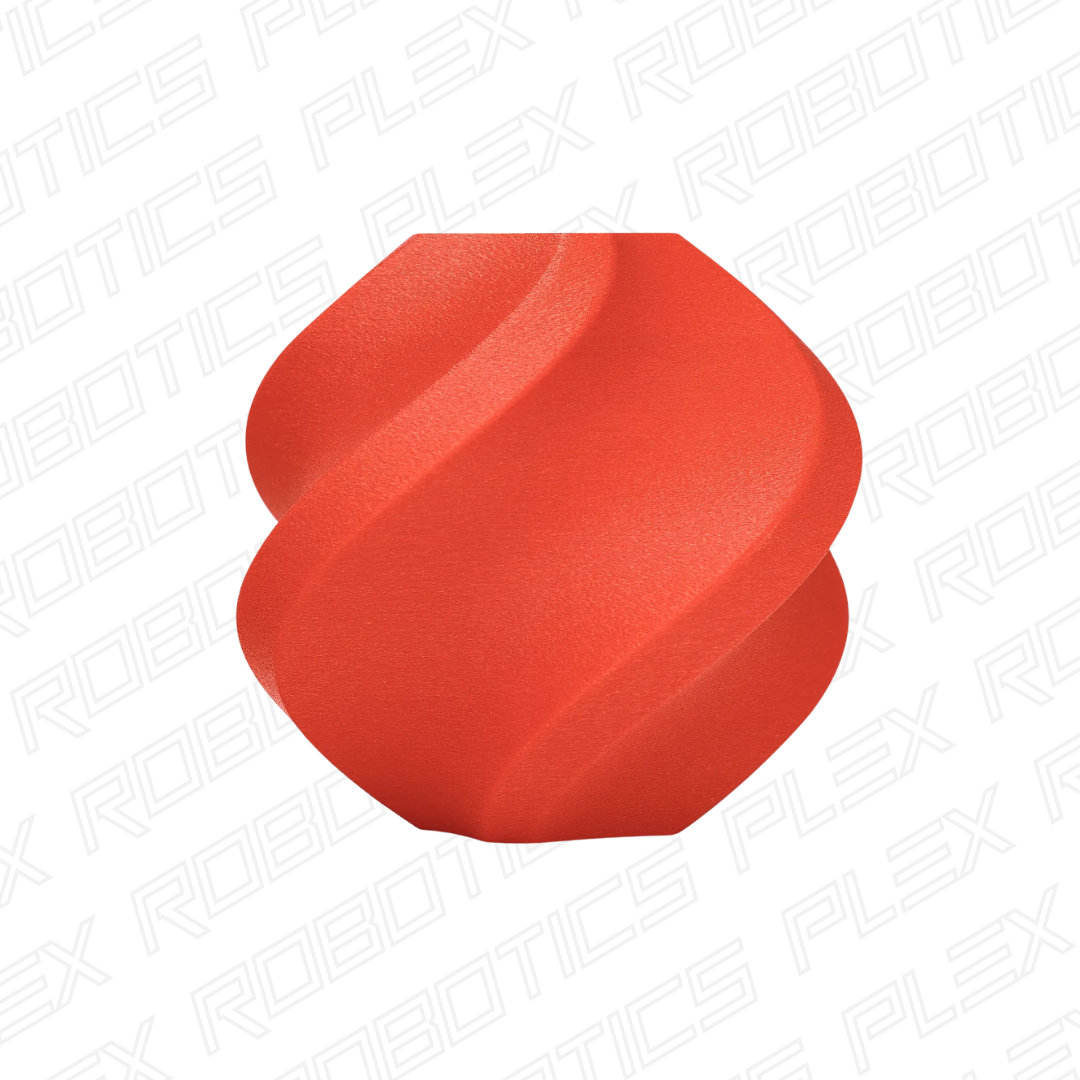

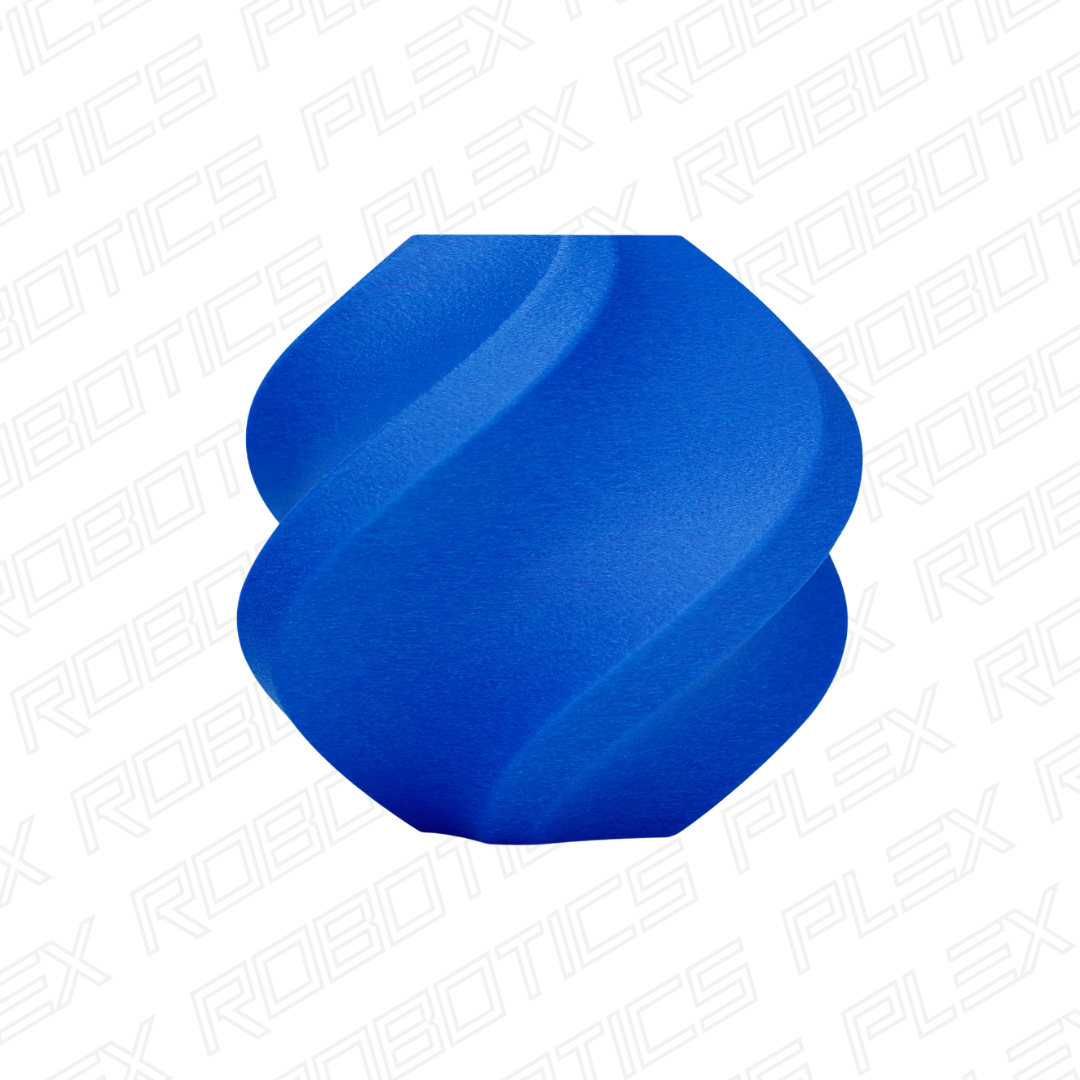

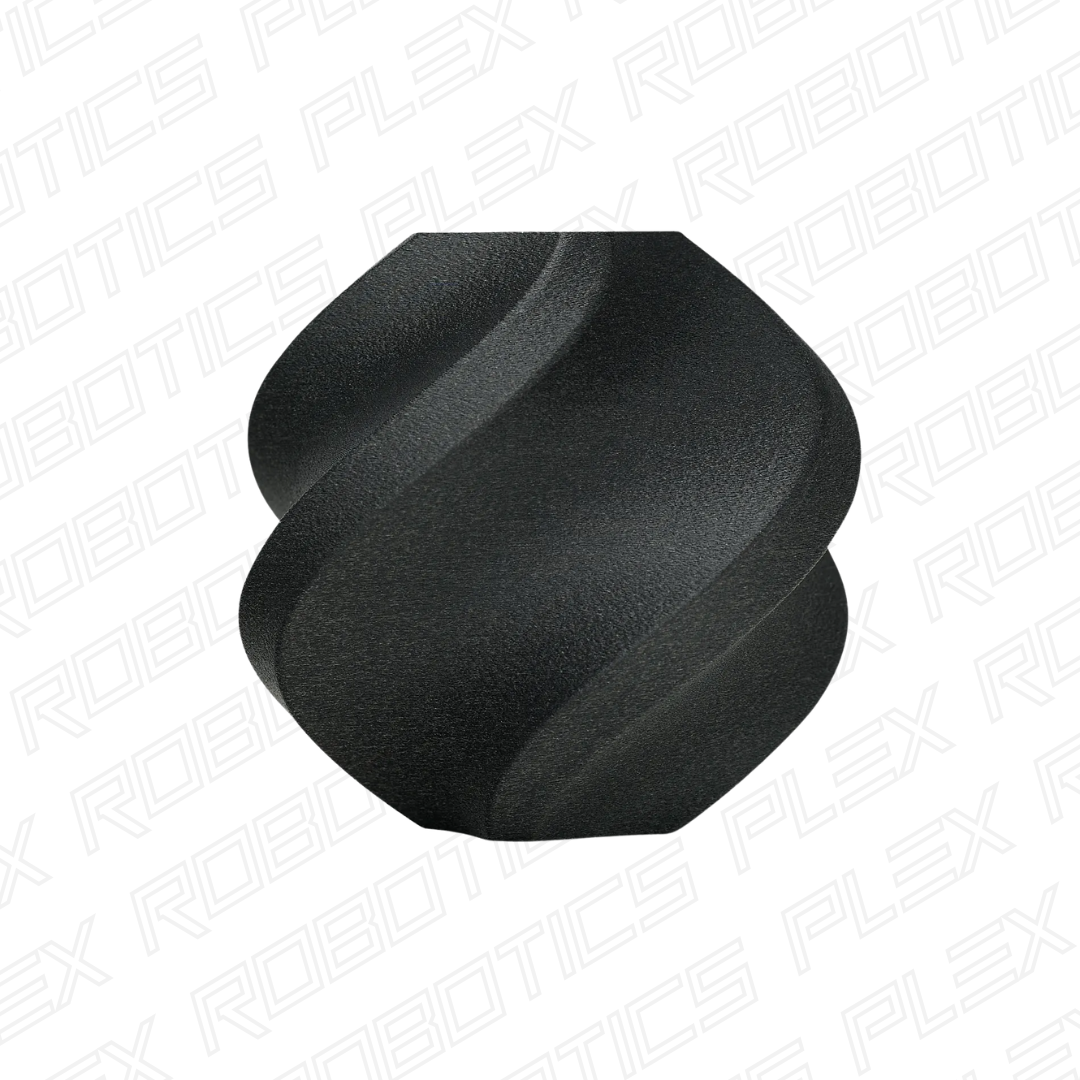

Fine Matte Finish

The seamless matte finish, coupled with nearly invisible layer lines, gives ABS-GF a smooth appearance, making it ideal for decorative and fine-grained parts.

Water Resistance & Built to Last

With improved water resistance and durability, Bambu ABS-GF is ideal for printing long-lasting production and household items, like mechanical casings, connectors and molds.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | Smooth PEI Plate, Textured PEI Plate | Cool Plate SuperTack |

| Hotend | Hotend with Hardened Steel 0.4mm / 0.6mm (recommended) / 0.8 mm | Hotend with Stainless Steel Nozzle All Size |

| Glue | Bambu Liquid Glue Glue Stick |

/ |

ABS-GF Hex Code Table

| Color | Hex Code | Display |

| White | #FFFFFF | |

| Gray | #C6C6C6 | |

| Yellow | #FFE133 | |

| Orange | #F48438 | |

| Red | #E83100 | |

| Green | #61BF36 | |

| Blue | #0C3B95 | |

| Black | #000000 |

Parameters Comparison

Learn more different filaments comparison on Bambu Filament Guide >>

| ABS |

ABS-GF

|

PA6-GF | |

| Composition | Acrylonitrile - butadiene - styrene |

Acrylonitrile - butadiene - styrene,

glass fiber |

PA6, glass fiber |

| AMS Compatibility | YES |

YES

|

YES |

| Dry Out Before Use | Recommended |

Recommended

|

Required |

| Printing Speed | < 300 mm/s |

< 180 mm/s

|

< 130 mm/s |

| Printer Type | Enclosure |

Enclosure

|

Enclosure |

| Toughness (Impact Strength - XY) | 39.3 kJ/m² |

14.5 kJ/m²

|

27.2 kJ/m² |

| Strength (Bending Strength - XY) | 62 MPa |

68 MPa

|

120 MPa |

| Layer Strength (Bending Strength - Z) | 39 MPa |

46 MPa

|

51 MPa |

| Stiffness (Bending Modulus - XY) | 1880 MPa |

2860 MPa

|

3670 MPa |

| Layer Adhesion (Impact Strength - Z) | 7.4 kJ/m² |

5.3 kJ/m²

|

4.1 kJ/m² |

| Heat Resistance(HDT, 0.45 MPa) | 87 °C |

99 °C

|

182 °C |

| Saturated Water Absorption Rate/%(25 °C, 55% RH) | 0.65 |

0.53

|

2.56 |

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System).

Load and print! No more tedious setting steps.

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 80 °C, 8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 240 - 270 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Printing Speed | < 180 mm/s |

| Physical Properties | |

| Density | 1.08 g/cm³ |

| Vicat Softening Temperature | 103 °C |

| Heat Deflection Temperature | 99 °C |

| Melting Temperature | 202 °C |

| Melt Index | 7.56 ± 1.4 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 36 ± 3 MPa |

| Breaking Elongation Rate | 6.3% ± 1.2% |

| Bending Modulus | 2860 ± 130 MPa |

| Bending Strength | 68 ± 4 MPa |

| Impact Strength | 14.5 ± 1.5 kJ/m² |